Cleaning tank containers requires water, energy and detergents. Thanks to innovative recycling techniques, Stolt Tank Containers keeps consumption of these to a minimum.

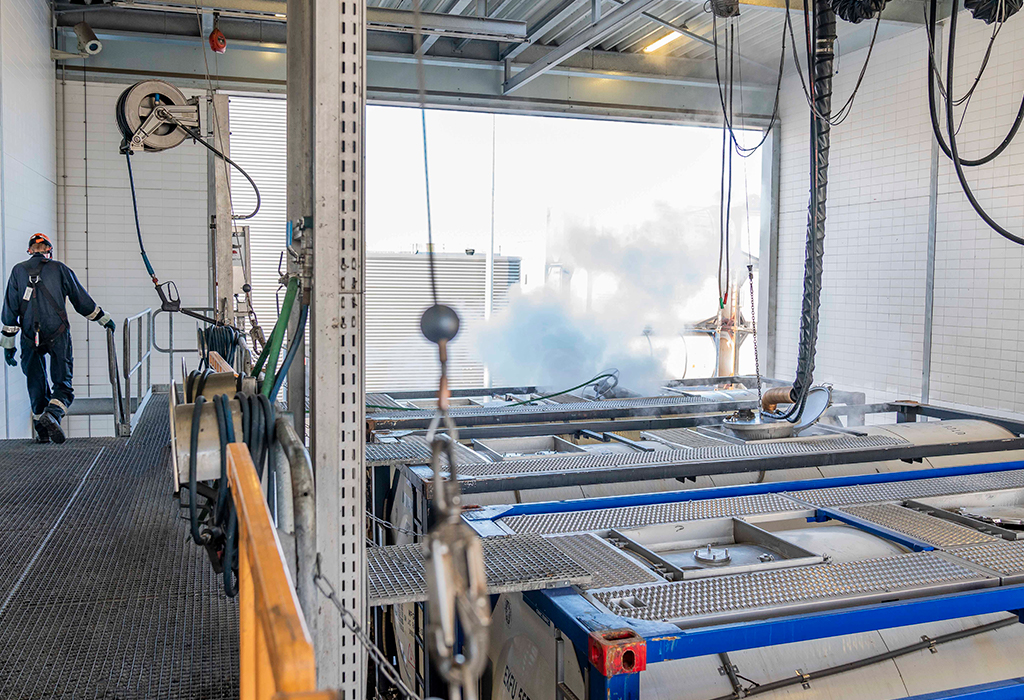

At Stolt Tank Containers, we’re innovating the processes in our cleaning depots to recycle water and energy, as well as minimising the need for additives and detergents. This is resulting in significantly less waste, lower costs and a notably more planet-friendly tank cleaning operation.

Stolt Container Terminal Moerdijk is an excellent example. The system we recently installed there is expected to reduce wastewater discharge by 70% and retain 23°C of cleaning water temperature for reuse. This flagship facility is setting the standards for proven technologies which are being rolled out at our other cleaning depots all around the world.

Water recycling

Wastewater from tank container cleaning processes is all being drained into our depots’ own wastewater installations, where it is processed via state-of-the art technology for re-use.

This involves:

- Separation of oils and fats

- Physical-chemical treatment

- Biological treatment

- Enhanced Effluent Polishing

o Membrane bioreactor (ultrafiltration)

o Reversed osmosis (nano-filtration)

o Active carbon absorption

o Sand filtration

The cleaned water is of drinking quality standard, which makes it good enough for us to use all over again for cleaning chemical tank containers.

** Intake of fresh water (at Moerdijk) will be reduced by 21,000m3 per year. And discharge of wastewater into the public sewer will decrease from 30,000 to 9,000 m3 per year. **

Energy efficiency

However, thanks to our investment in special rotating heat exchangers, we are able to recover a large proportion of the thermal energy in our own tank container cleaning wastewater. This gives us a starting point of 23 degrees, thereby meaning we have 15 degrees less water-heating to do. And that results in a huge saving on our natural gas consumption.

What’s more, this transfer of heat cools the wastewater to a point where it enables our oil fat separator to operate more efficiently.

** At Moerdijk, consumption of natural gas is expected to reduce by 57,000m3 per year, saving 37,000kg of CO2 emissions. That’s equivalent to 1 year’s household gas for every employee (45) at the Moerdijk depot. **

Minimised use of detergents and additives

The re-usable water that comes out of our enhanced filtration system is very low in salts and minerals. This soft water doesn’t require additives prior to being re-heated in our boilers, and lessens the amount of detergent needed for effective cleaning. ** At Moerdijk, we expect to reduce chemical consumption by around 2,000kg a year. **

Continually pushing the boundaries

At Stolt Tank Containers, we are continuously challenging ourselves to find ways to operate more sustainably, efficiently and cost-effectively. Our global depot network works closely together, sharing ideas and developing innovations in the pursuit of the ambitious goals we’ve set ourselves.