Posted on 13 December 2023

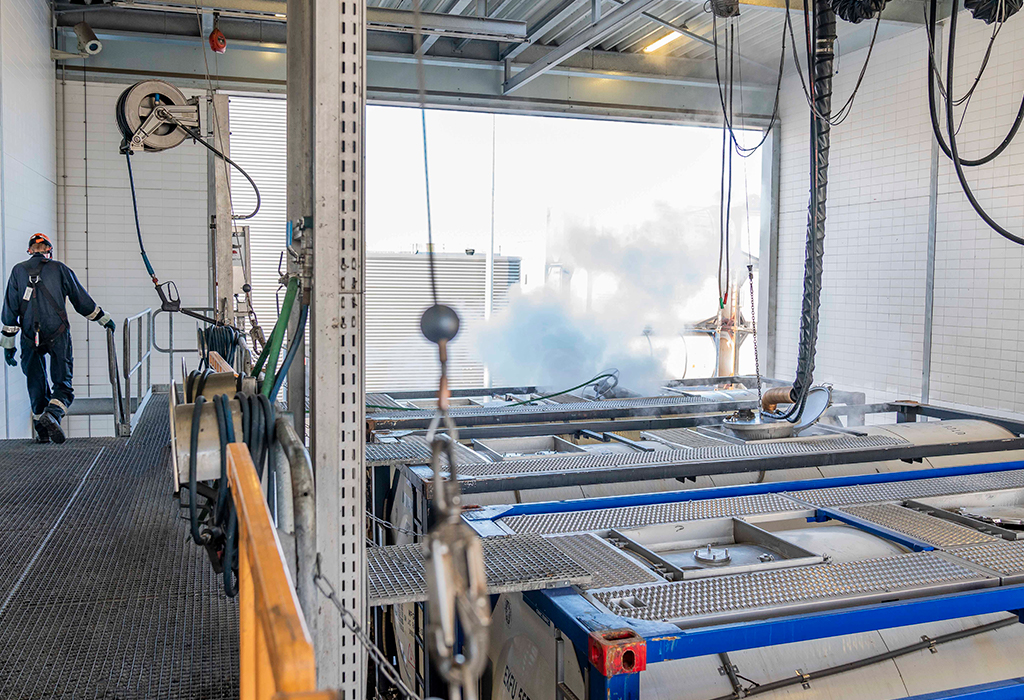

We prioritise safety for people and the environment, and we are proud to have a safety culture that goes beyond legal compliance requirements. This means we measure, monitor, and report safety indicators in line with established procedures and compliance requirements, and proactively track and deliver training to mitigate risks and protect colleagues.

As a data-driven company, we’re constantly monitoring our safety performance with key leading and lagging safety indicators to help us further improve our safety performance. With more insights being available, we can better prevent accidents from happening and enhance our safety performance in our depots and while transporting tanks using various modalities.

Lagging indicators are incidents or near misses that have occurred in depots or during transport. These indicators, such as Total Recordable Case Frequency (TRCF), Lost Time Injury Frequency (LTIF), and the number of serious incidents, tell us how often things go wrong. On the other hand, leading indicators are risk factors that highlight how often things could potentially go wrong. By monitoring both leading and lagging indicators, we can quantify the results of our safety culture.

Harnessing data to go beyond legal compliance.

As part of our internal safety standards, we ask our customers to ensure that the safety data sheets (SDS) of products are accurate and no more than three years old. We seek to have the correct up-to-date information, to ensure the safe handling and transport of products by our colleagues and service partners. Additionally, for inhibited cargo, we ask for a valid Certificate of Inhibition (COI) stating the right information so we can share this information with the parties involved. As part of our leading indicators, we also track when loaded tanks are reaching critical periods of inhibitor effectiveness expiry so we can remind customers to take necessary actions.

At Stolt Tank Containers, we advise our customers on the minimum and maximum fill ratio requirements of our tanks. We monitor this to be within this permissible range to ensure that the tanks remain compliant with the regulatory requirements and safety protocols. Transporting tanks that are not filled in accordance with the minimum and maximum fill ratio is a greater risk to supply chain safety. While underfilled tanks increase the risk of the vehicle rolling over due to the uncontrolled movement of the product within the tank, overfilling tanks may cause safety incidents like cargo overflow due to product expansion during heating for offloading or while transiting through hotter ambient temperatures.

We also monitor the test dates of our tanks which are with our customers and may be still loaded. This proactive monitoring allows us to inform customers to return tanks and so we can timely test them to prevent incidents, such as regulatory noncompliance, leaks, and explosions from happening.

At Stolt Tank Containers, we are committed and vigilant when it comes to safety. When we have the right data and insights on our tanks and the products we carry, we’re better equipped to monitor, manage, and ensure compliance with our policies across the world.

To learn more about safety at Stolt Tank Containers and Stolt-Nielsen, click HERE.